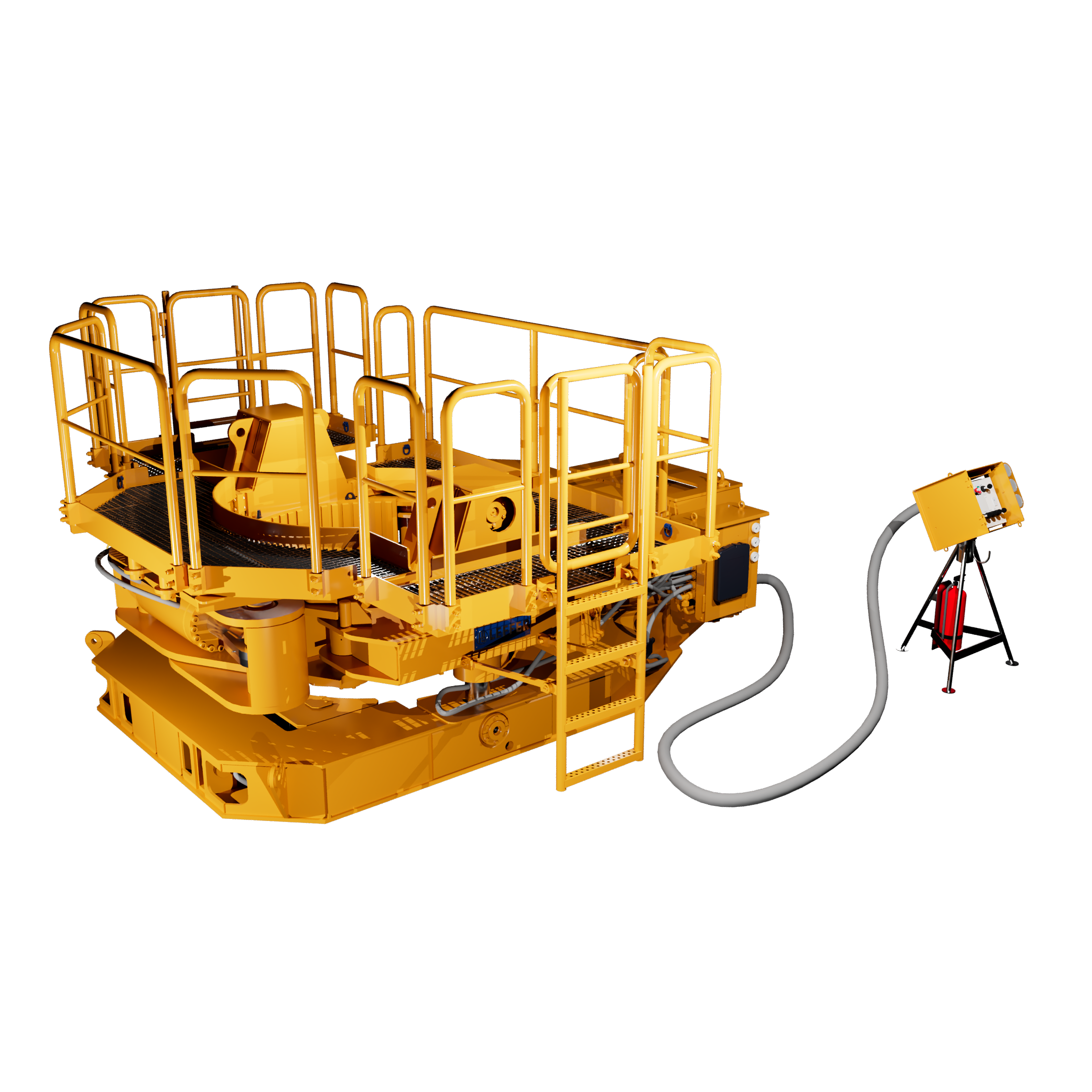

Casing machines KL type for combined use rotary drilling rigs

LEFFER offers short-design casing machines (type KL) to support the rotary drilling rig. In general, LEFFER casing machines have been designed based on specific experience.

The five-part clamping collar that surrounds the drill pipe prevents plastic damage to the pipe circumference and ensures efficient and force-fit transmission of torques and vertical forces.

- Thanks to our reduction inserts, our casing machines can be converted to small diameters in just a few minutes.

- The moment-resistant attachment to the excavator guarantees the transmission of the full oscillating movement: This enables the pipe string to rotate up to 25° per oscillating movement.

- The low height on the excavator side allows 360° movement of the excavator upper carriage even when coupled.

With LEFFER casing machines, casing and drilling can be carried out simultaneously. Control can be via the carrier’s on-board hydraulics or LEFFER’s own power unit.

Model types

Casing machines | Drilling diameter in mm | Lifting force in N | Torque in kNm |

|---|---|---|---|

VRM 100 KL | 500–1000 | 920 | 800 |

VRM 118 KL | 620–1180 | 1200 | 1250 |

VRM 120KL | 620–1200 | 1200 | 1250 |

VRM 130 KL | 750–1300 | 1700 | 1600 |

VRM 150 KL | 750–1500 | 1700 | 1850 |

VRM 200 KL | 1200–2000 | 2250 | 2700 |

VRM 220 KL | 1500–2200 | 2250 | 2900 |

VRM 250 KL | 1800–2500 | 2950 | 3250 |